ABCO Subsea is often charged with developing solutions to unique problems encountered by our clients offshore. Here are some of the company’s recent research and development case studies.

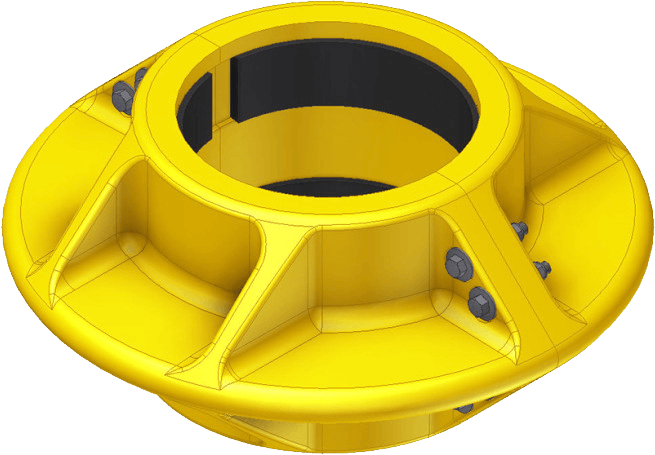

Axially Rotating (AR) Clamp Base

Problem: Wire ropes were becoming entangled with an umbilical when the two lines were being retrieved.

Solution: ABCO Subsea designed an Axially Rotating (AR) Clamp Base that holds a wire rope separate from an umbilical and prevents the two lines from becoming entangled during retrieval. The wire rope is able to spin in place.

Droop Line Bumpers

Problem: A client’s flexible pipe was clashing against other lines and against their moon pool during high weather conditions.

Solution: ABCO Subsea developed Droop Line Bumpers, polyurethane disks that provide a protective frame around umbilicals or flexible pipe. Droop Line Bumpers are easy to assemble in the field and cost-effective

Line Support Clamp

Problem: A client’s rigid conduit line was being damaged when their riser was moved from horizontal to vertical on the drill floor. The riser would swing forward, sometimes crashing the rigid conduit line into a fixed structure.

Solution: ABCO Subsea designed an easy-to-assemble polyurethane part, the Line Support Clamp, that supports the rigid conduit line between the riser tube and the conduit line.

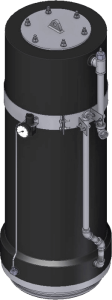

Subsea Electronic Module (SEM) Cooling System

Problem: A client’s Subsea Electronics Module was overheating when the SEM was recovered for routine maintenance. When an SEM is in the use in the field, the temperature of the surrounding seawater keeps the unit cool.

Solution: ABCO Subsea designed the industry’s first SEM Cooling System, a cylindrical polyurethane shell that is fitted over the top of an SEM and connects to a pack-off seal. A water hose is connected to an inlet on the shell and freshwater swirls around the SEM, keeping the module cool, and exits the shell through an outlet.

Topside Umbilical Termination Assembly (TUTA)

Problem: A client needed a TUTA for an offshore rig with more durability and protective features to withstand a hazardous environment.

Solution: ABCO Subsea designed a TUTA with a protective enclosure to better secure the client’s interface between its umbilical and topside control equipment.